The mechanical is being replaced by the electronic, and new skills are needed to fix or just to know what is happening in a vehicle.

Some mechanics are already saying: “It seems that, instead of cars, we repair household appliances.” And they are right: automobiles have changed considerably since their inception, but in recent years the leap has been spectacular. From those parts that were repaired based on learned theory and simple skills, systems have evolved that combine technology with the analogue. And some are barely analogical at all. For this reason, although classic elements continue to be maintained and timeless lessons are used, dealing with a new car has more to do with deciphering the operation of a digital device than with tightening a nut.

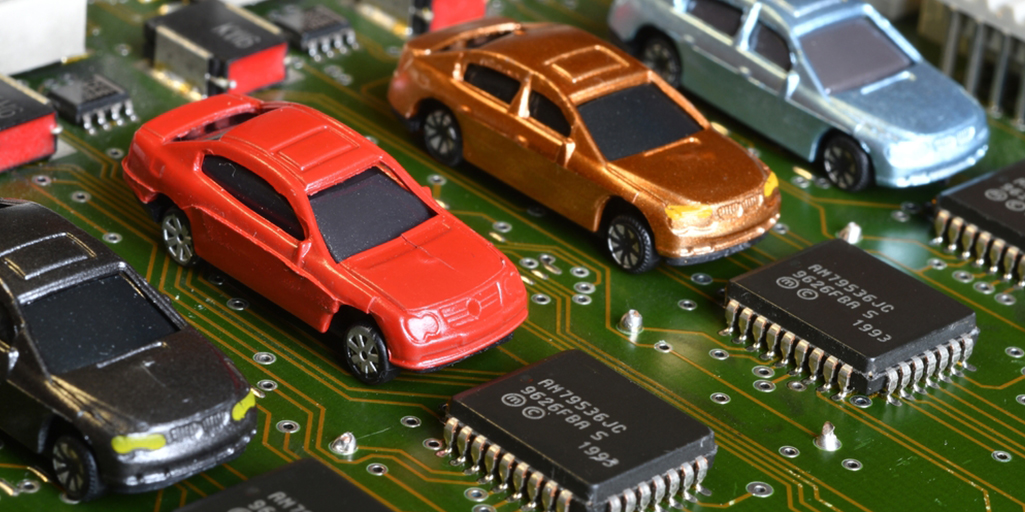

We have gone from the screwdriver to the chip. Failures are no longer only measured in physical damage, but in cables that do not perform their job or in tiny parts where a circuit fails. The automotive specialist and enthusiast Rubén Fidalgo explains this change since the Volkswagen Type 3 was presented at the end of the 1960s. This vehicle, he points out, was the pioneer because “it had the first electronic gasoline injection system and it is the one who began to pave the way” to show that “mastering electrons is more important than knowing how to tighten a screw.”

Fidalgo has been a technical assistance advisor and dealership manager, so he considers that he “has seen the bull from the sidelines” in this evolution and he concludes that, now, “mechanical work is much more complicated.” “It is true that current cars have their own integrated diagnostic systems and that they take note of all the anomalies that occur, but the problem is that you have to understand how the car works in order to know how to diagnose it correctly,” he argues.

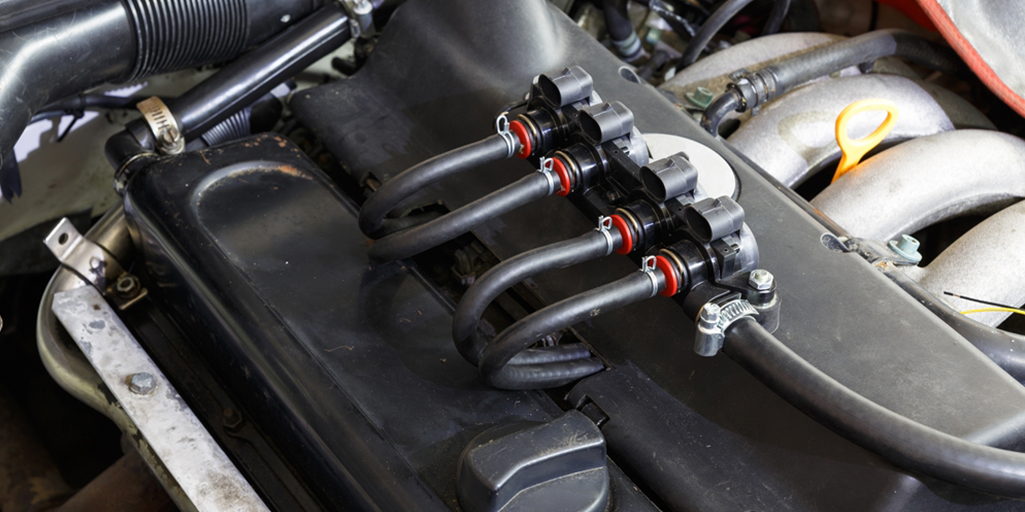

As he says, the key basis of a good mechanic today is knowing precisely how to offer an appropriate diagnosis. And this goes through a procedure that did not exist before. The first phase is to connect the diagnostic machine to the on-board computer and see what it says. But, in addition, you have to know the car. Understanding the engine and other components to notice errors that machines cannot solve (which is lucky, because, if not, we would already be in that future, which is more than likely to come to pass, in which robots replace humans). The specialist describes some cases of how the switchboard, that “electronic brain” that we believe to be infallible, turns out to be wrong. And he insists that the profession is becoming more and more complex.

Such progress means that whoever wants to enter the trade must have some “virtues,” indicates the professional, who describes these new challenges. “A mechanic must have knowledge of electronics. In the past, it was enough for him to know what a battery, a dynamo and a switch were to master the mechanics and electricity of a car. At present, electronics is the main cause of breakdowns in cars and it is a priority to understand it”, he points out in one of the articles he has written on the matter.

“Car mechanics are increasingly reliable. Nowadays, failures that were once commonplace are rare. Engines are barely rectified, the power steering no longer fails because a simple belt breaks (now they are electric), and so on. It is the electronic failures and the multitude of auxiliary systems that the cars have that are causing the most problems. To repair a car nowadays it is necessary to have a huge electronic arsenal,” he stresses, listing more problems derived from this change, such as knowing how to enter the codes of the cars that start with the start and stop system.

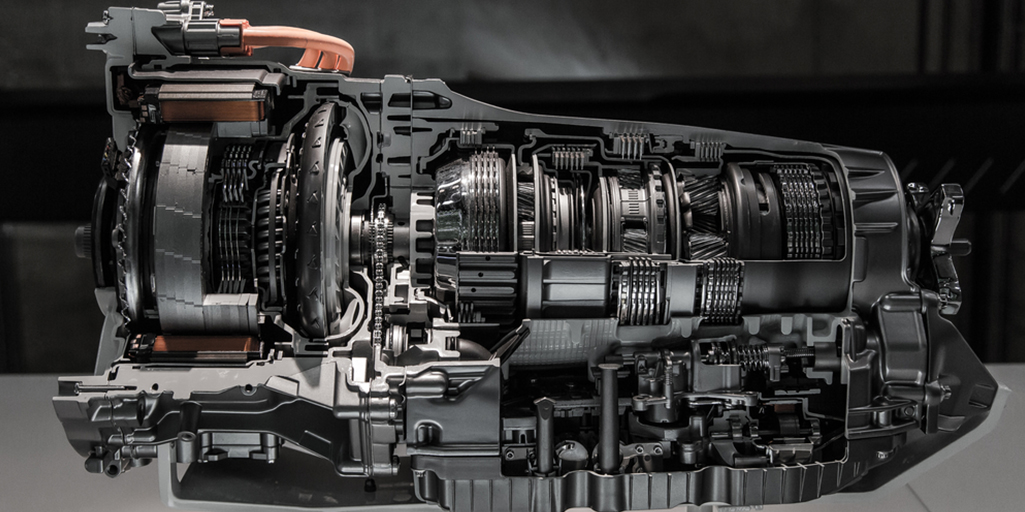

“I don’t want to say that the profession of mechanic is going to disappear, but, of course, it is already changing and it will continue to do so,” he explains. “On the other hand, new technologies are a business alternative, because they will have to be repaired; and this is where my first piece of advice is: specialize.” One of these specializations would be, for example, in automatic cars.

As a market “in clear expansion”, according to Fidalgo, it would be a good niche. “In the United States they have been the majority for decades, but in Europe it is now when they are clearly expanding. From just 2% five years ago, the current market for automatic versions is close to 20%, so it has grown almost tenfold. Knowing how to diagnose and repair automatic cars has a future. The complicated thing is that there are several types of automatic gearboxes: robotic, torque converter, double-clutch continuous variator… and, in addition, they require quite expensive special machinery for their repair,” he points out. He also recommends, of course, learning English and the most recent advances in the technological field.

Another avenue to focus on would be hybrid and electric vehicles. “It is true that they are more reliable and break down less often, but they do; and currently there are hardly any specialized workshops. Although there is not much demand, there is also no supply, so it is a good alternative,” he notes. He tells us about the verification of sensors for autonomous cars (“Although they are in the future, cars increasingly include driving assistance,” he clarifies) and augmented reality technology.

“With it, the workshop operators will have a virtual representation of what they should be doing at each step. For example, if the car has a failure in the navigation module, images will show you the order in which you must disassemble and check the elements. In addition, the system will ask you to answer a series of questions. If in a step it asks us to check if there is power to a cable, we will have to answer yes or no. Depending on our response, the guide will follow one procedure or another, as appropriate,” he says. As we said above, mechanical work now is very different from that of just a few years ago. And cars are not yet refrigerators or printers, but they are becoming more and more like them.